Prevention of hazardous spills should be the initial aim so the correct identification of chemicals and materials that constitute the label of being hazardous should be the first challenge. The Health and Safety Executive (HSE) gives good information on what constitutes being hazardous and explains how to control hazardous substances at work and comply with the Control of Substances Hazardous to Health (COSHH) Regulations 2002.

The operatives who deal with an accidental spill are the most important asset in ensuring the safe protection of your employees, plant, site and the environment from any resulting pollution incident. Any spill prevention strategy needs to be effective and easily updated as legislation changes and site situations are altered. The required response plan should always be designed and operated around the staff training that accompanies it. The purchase of the correct spill kits and equipment is important but knowing how to use and apply them is the key to effective control.

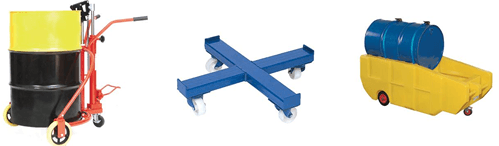

The correct movement of hazardous materials will require the use of suitable equipment like trolleys, pallets, lifters and other material handling equipment that can be purchased after consultation with a reputable supplier. Different tasks require different equipment and of course the associated operator training to fit in with your response plan.

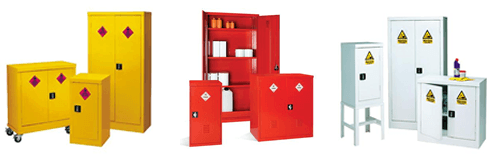

Once materials have been moved to a required point within your site they then need to be stored correctly. Once again some consultation with a supplier will be required. The type of storage equipment depends largely on whether the materials are to be use immediately or are being stored for later use. Longer term storage solutions are numerous and often have the added need for an element of security for that product. Goods in use can easily be stored on a trolley standing on bunded flooring or a pallet fitted with a bund that gives the operator the required safety in knowing that any small accidental spills will be contained within the spill bund. A bund can then easily be drained off into the appropriate place or vessel once the operation of use has finished.

Correct spill training helps towards ISO14001, meets with regulations including the Pollution Prevention Guidelines (PPG21) and Control of Major Accident Hazards Regulations (COMAH) and also forms part of your Response Plan for spills. Spill training provides your operators with familiarity of your Response Plan. It also reduces the likelihood of a pollution incident, reduces the potential cost implication that can be associated with a spill response. It also provides the operators with the ability to safely manage spills and finally ensures that staff are aware of the potential risks associated with accidental spills. Major pollution incidents can often be prevented if a problem is recognised at an early stage and appropriate actions are taken. Planning, prevention and response strategies all need to form part of the carefully addressed techniques employed by employers. The drawing up and implementation of appropriate and effective emergency spill control procedures are the building blocks to a safe management system. The response procedures should look at the variety of spill control products available:

- Hazardous materials must be contained first in order to prevent spread of the material to other areas. This may need the employment of absorption products, sand bags, booms or absorbent pads.

- Naturally the spill should be treated with the appropriate chemicals to neutralise the effects of potential danger.

- Hazardous materials in a fine dusty form should be cleaned up by using vacuum cleaners and not by dry brushing. Toxic materials one conforming to type H (BS 5415) should be used. Waste should be cleared away and not left to potential spread.

The purchase and use of the correct personal protection equipment (PPE) is of utmost importance. There is a huge range of equipment that will need to be employed when operatives deal with spills. Gloves, boots, eyewear, protective overalls, breathing apparatus, hard hats, respiratory protection, hearing protection and hand tools will all be necessary basic requirements.

Moving chemicals and dangerous substances

Drum Handling Equipment

Storing chemicals and dangerous substances

Bunded Anti-spill Storage

Hazardous Substance Storage

Cleaning up spillages safely

Spill Control Products

PPE Equipment