When a large company makes contact with you on the back of previous dealings, it’s always comforting to be in the knowledge that the work you have carried out before is appreciated. Being invited back to help with new and exciting projects, is extra special for us!

Our sales manager Jonathan Ball visited the site for a meeting with the General Products Manager and Ops Director to discuss the new floor plan layout for a distribution network in Northampton and to find a solution for the client so they could easily feed off from their new order picking conveyor system directly to the individual packaging operatives.

The customer was having a total revamp of their ordering system and the new computerised conveyor would scan and pick orders and place them onto the conveyor. The customer had empty tote boxes that would be scanned as they passed through various points along the conveyor and they would be sent off to the relevant operator to pick and pack orders into tote boxes.

The purpose of our visit was to see first-hand the layout and operation in its current state and to grasp the client’s needs in order to find a solution to enable a smooth transaction as the totes moved around the overhead conveyor system.

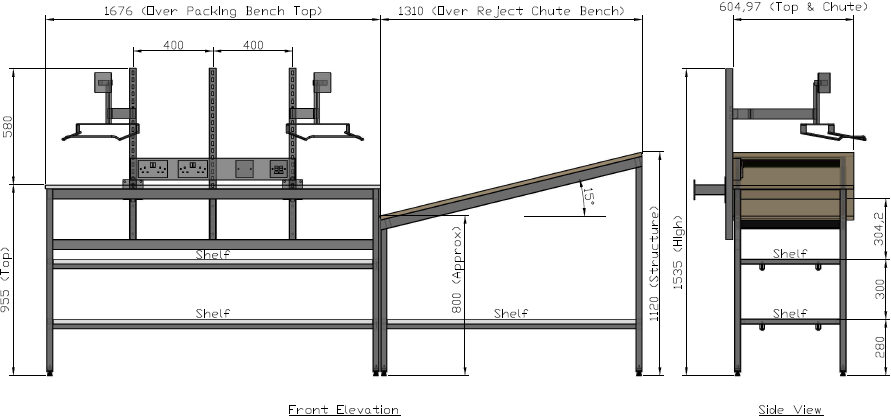

By taking various measurements and discussing the machinery layout planned we went about designing a bespoke packaging bench with a chute to allow the totes to arrive at the operative’s workstation area ready to pick and pack and then send upon its way to the next destination.

Drawing up a plan, listening to the customers’ needs, thinking about the hard wearing materials needed and of course all of the crucial measurements ensured that all aspects of this project came together seamlessly.

Drawing up a plan, listening to the customers’ needs, thinking about the hard wearing materials needed and of course all of the crucial measurements ensured that all aspects of this project came together seamlessly.

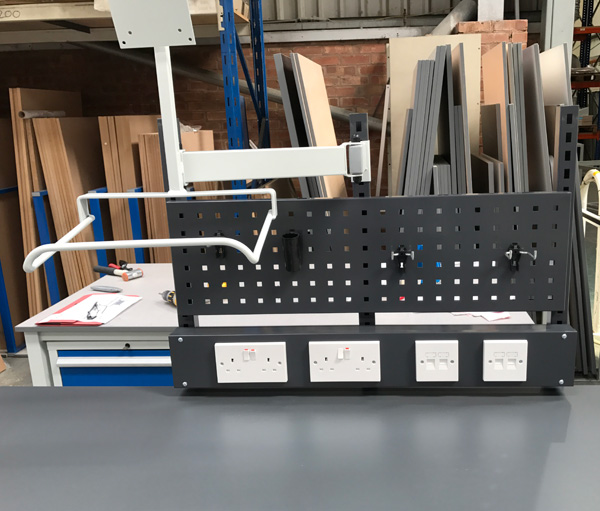

The customer also had computer monitors and keyboards that needed to be mounted onto the benches so needed the appropriate stands for both of these as well as power supply sockets along the back with ethernet connections.

We had to design a support area for the modem on each bench and the customer also uses a hand held scanner that had to be stored on the workbench so we took all those details and documented the physical size to ensure we created a holder purpose built for these items within the rear support posts of the bench.

Special Packing Bench

- 21 off, 1650x600x955 Laminate top welded frame bench C/W 2 x 1600x450 lower shelves (laminate).

- 2 packs (5 per pack) of half-lower shelf dividers.

- Rear support posts (1 pair per bench).

- 2 off monitor and keyboard arms.

- 21 off 1300x600x 955/1120 h sloping-top bench, Stainless Steel top C/W 2 off lower shelves.

- Optional extra additional ball units to be fitted to main bench next to the conveyor, this will be an integral part of the bench - based on 20 ball units, 5 x 4 rows was ideal for the client to consider if they felt necessary. Above benches to be right and left handed.

- 2 off 1200x600 laminate top workbench (for rejects), C/W 2 off lower shelves.

For the work top surface bamboo was mentioned by the client as a possible hardwearing option but the cost would have been excessive so we gathered details and samples of stainless steel and galvanised steel to evaluate. We ended up using a stainless steel top for the sloping top bench, which will offer more in the way of longevity compared with a steel painted top. The main bench is a grey laminate top.

For regular Action Handling updates, follow us on Facebook and Twitter, Sign up to our monthly newsletter for company news and information.