If I was to say to you Southend On Sea, your first thoughts might be ones of a typical British seaside resort, famous pier, amusement arcades and Punch and Judy shows on the beach. You would be forgiven for not thinking of a major airport or a world leader in aircraft seating manufacture. But it is true that both are tucked away in the south east of England along the Essex coast.

Our customer of 18 years has developed an amazing range of executive pilot and passenger aircraft seating systems that are supplied to many of the leading aircraft manufacturers. The company is now in its third generation of family ownership. We were naturally pleased to have been called upon to supply a quantity of bespoke box trucks to help with their business expansion in these very exciting times for this Essex site.

This week saw us ship another variation of over several hundred box trucks to the customer. Our designs have helped improve the wellbeing and performance of the staff. We have seen the company move on from how things were back in 2001, when staff had to carry rolls of material from racks, walk to workstations and then pick other component materials from steel bin units, all whilst standing up for long periods of time. Then there was also the picking of the various cloths, leathers and components which was a repeat process throughout the working day. The toll of leaning, twisting and reaching would lead to poor posture, muscular strains, injury and ultimately loss of productivity.

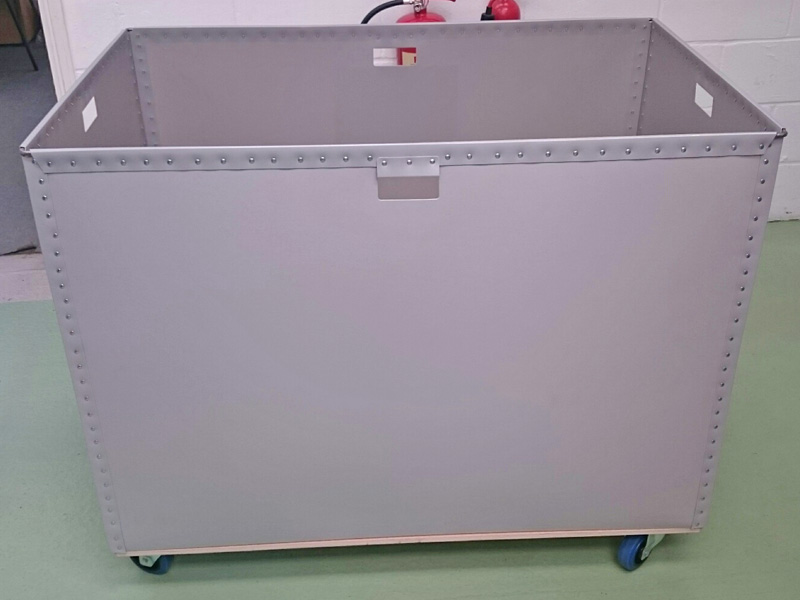

Thankfully today, with the far greater understanding of ergonomics within the workplace, the use of our specialist box trucks has enabled our customer to hold a stock of pre-cut materials to be stored safely without the risk of damage before for the next stage of production. This has been crucial as this ever expanding business recently won yet another large contract with Boeing.

Staff can simply replenish consumables and materials by presenting the box trucks at the assembly line and then be ready to fit the seats with all the required materials and components. By using our box trucks within their organisation and the subsequent spin off of small tote style boxes that are fitted with lids for smaller items, each task is now made considerably easier for their employees. The box truck has the right attributes required to be a useful tool in this particular situation as it is lightweight, strong and easy to move around, making life so much easier and better for the workforce on site.

The box trucks and containers were originally made from fibreboard but as time has moved on the demand for even lighter and stronger materials has become ever more increasing. We had to look at alternative construction techniques to fulfil the needs of our customers, so in 2016 we stopped using fibreboard and started to produce a range of box trucks manufactured from High Density Polyethylene (HDPE) sheet. This provides far greater strength with an even lighter tare weight. As well as being used on our box trucks and containers, we also now supply a range of cases for carrying musical instruments, tools and laptops. The new HDPE box trucks are cut and creased around a mild steel rim. Reinforced with either steel or plastic three-way corners. We also offer a wide selection of handles, locks and hinges which are available to suit many different applications. We now stock HDPE in black, navy blue, royal blue, red, green, yellow and grey colours so that trucks can be differentiated in use or made to suit company colours.

For regular Action Handling updates, follow us on Facebook and Twitter, Sign up to our monthly newsletter for company news and information.