The US Military in Germany were looking to site some specialist welded cabinets that they use to store 'in-house military equipment’. Very hush hush, we can’t tell you what’s in them buddy!

Our brief was to design, manufacture and supply a fully secure mesh enclosure that could be used for that very purpose. This was to be a four-sided mesh steel infill run complete with a roof and individual doors to segregate each cage section. These sections were to be completely independent of each other in order to enable the client to disassemble and reassemble in numerous combinations dependent on specific requirements at any given time.

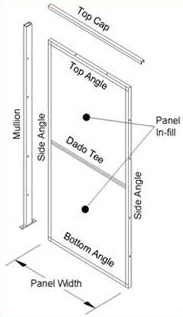

We were able to provide a subtle take on our standard single skin partition system. These were constructed using a formation of panels, support mullions and top capping. The support mullions are generally positioned at a maximum of 3.7m centres with 3 standard panels between and a single top cap connecting the 3 panels together. Once all these components are bolted together, they provide a rigid partition wall up to 3.66m high with double lift applications even higher if required. The cage was constructed in 50mm x 50mm x 10g mesh throughout and each compartment has a 2000mm high side hung door, 915mm wide supplied with a hasp and staple fitting suitable for padlock locking. The cages were then powder coated with a sandstone (BS 08B17) finish. We could have finished them in grey, graphite or white if the customer had requested.

When considering installing a single skin partition system, there are multiple door options available: single, double or sliding doors. All have door furniture accessories available and any glazing panels fitted are laminated safety glass. The panels are manufactured from cold rolled mild steel angle and cold rolled tees with sheet steel, weld mesh in-fill sheets spot welded together or glazed. Panels are bolted together using M8 bolts and floor fixed with pan head screws in 6mm plastic plugs. Standard panel widths are 1220mm, 915mm, 610mm and 305mm but we are able to bespoke-make to order almost any size. The same applies to the height of the panels, where the standard heights are 2440mm, 2700mm, 3050mm and 3660mm. Support mullions are manufactured from rectangular hollow section with a 10mm thick plate welded to the base of the mullion for floor fixing. Each mullion has a series of drilled and tapped holes along its height, ready to receive M8 fixing bolts to position the panels. All mullions are floor fixed with 12mm anchor bolts. The top edges of the panels are aligned with the top cap which is manufactured from a channel section and is generally 3.66m long.

We were naturally very pleased to receive a positive endorsement of our service from the customer as well: “Thank you to Jonathan and your team - your service from start to finish has been first class” - Nigel project manager.

For regular Action Handling updates, follow us on Facebook and Twitter, Sign up to our monthly newsletter for company news and information.